Once an order has been produced and inspected at our manufacturing plant, the components of the mobile barriers are palletized and loaded onto trucks for delivery to their final destination. Upon arrival, the customer or their contractor will unload the materials and begin assembly.

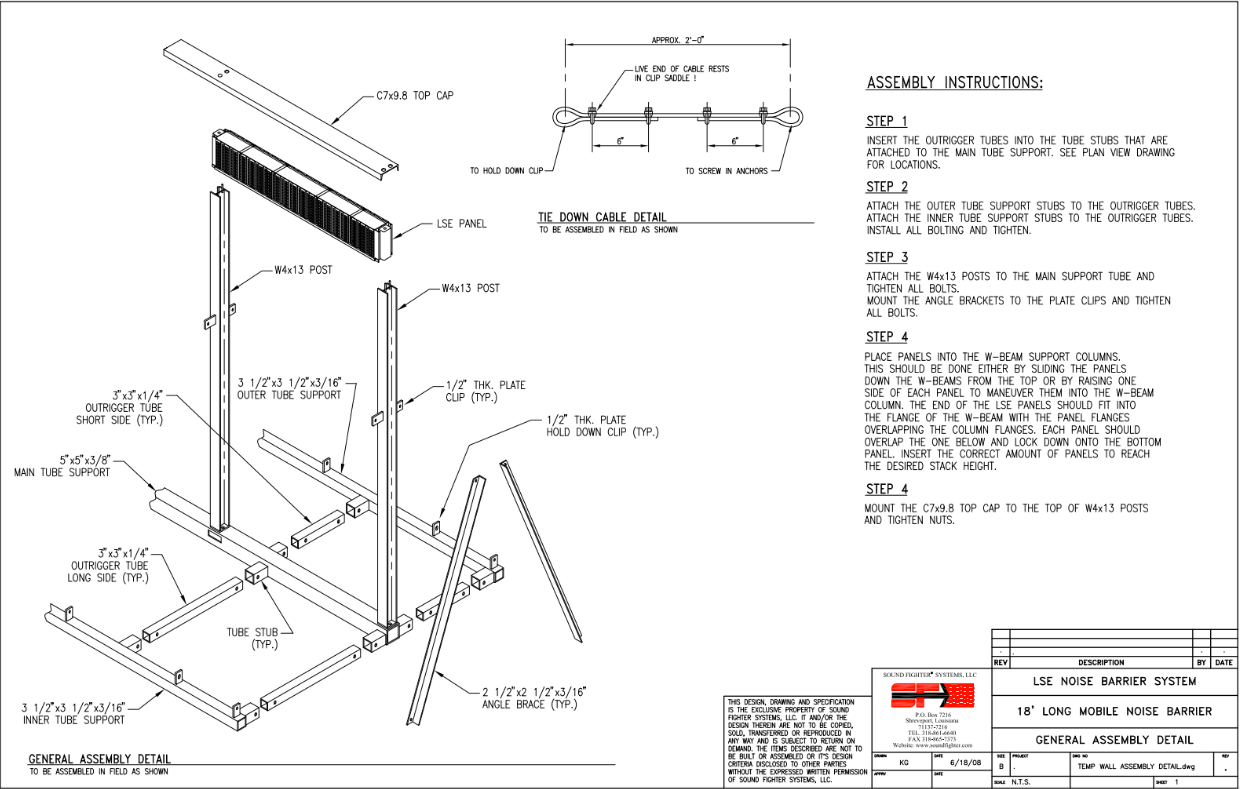

The barriers feature a bolt-up design, whereby no additional drilling, cutting or welding is required. A detailed installation drawing will be provided to the customer, which details all components and assembly instructions for our Mobile Noise Barriers.

The use of a 4-man crew is optimal for assembly and placement of final barrier into desired position -- One man to operate the lift for lifting the vertical beams into place, and three men for assembly of steel framework and sound panels. The lift operator can assist when beams are set.

We estimate 4-8 Total Man-Hours of labor required to assemble a single unit, respective to the size of the Mobile Barrier at hand.